Manufacturing Execution Systems

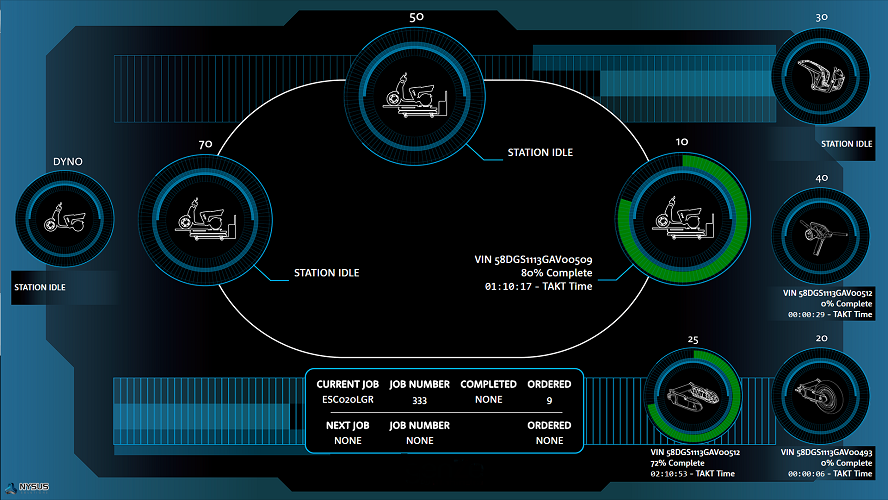

In a globally competitive environment every manufacturer must continue to strive for improvements in cost, quality, and lead time. The Nysus Solutions Manufacturing Execution System can facilitate dramatic improvements in all these areas.

- Home

- /

- MES

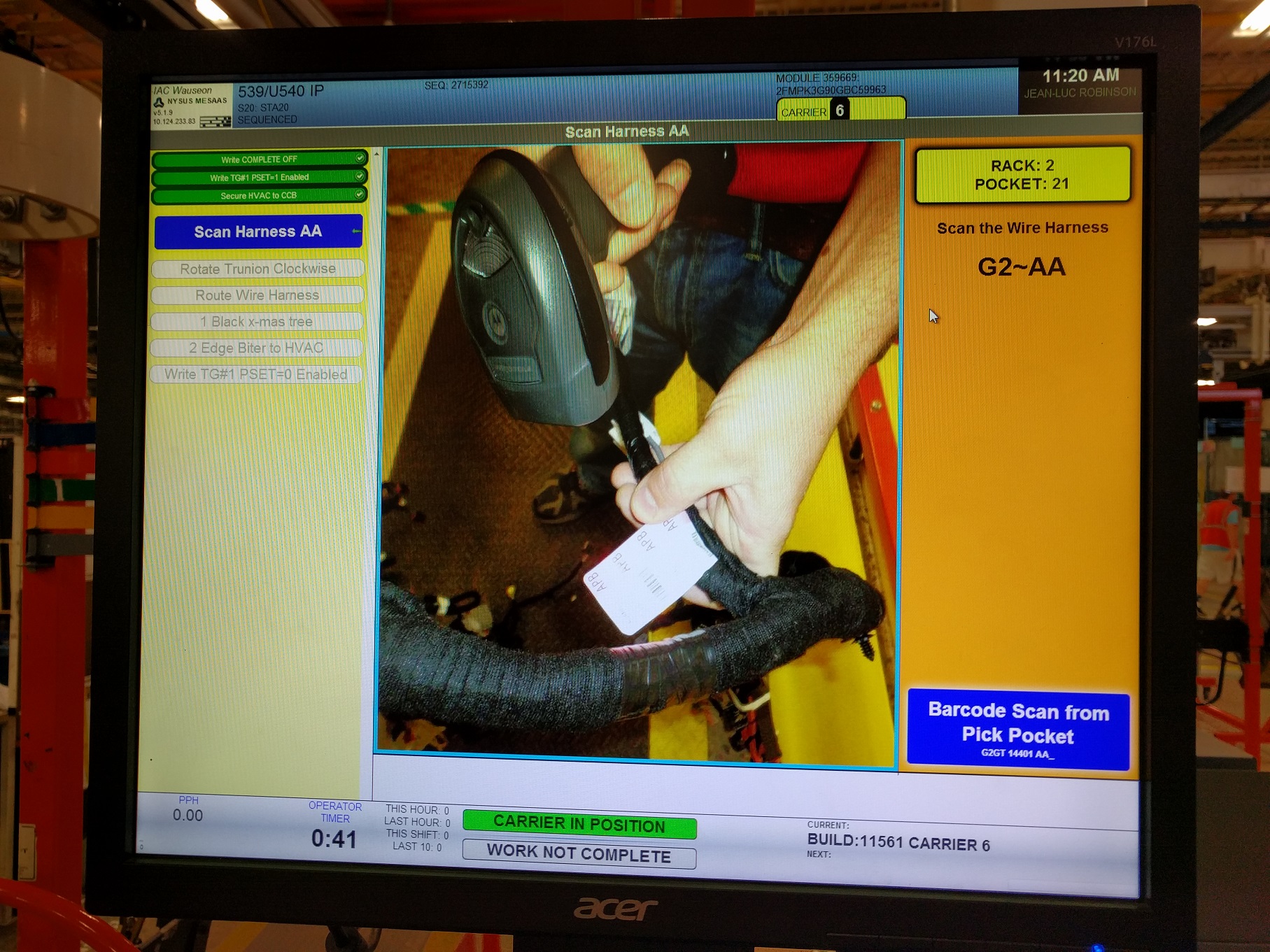

The Nysus Solutions Assembly Manufacturing Execution System is designed to simplify high complexity assembly processes through automated work instructions and integrated poka yoke systems. The entire process is tracked from start to finish including operators, PLC info, torque, sub components, vision images, and shipping details. Typical applications include automotive modules, full vehicle builds, ATV, aerospace, and appliance assembly.

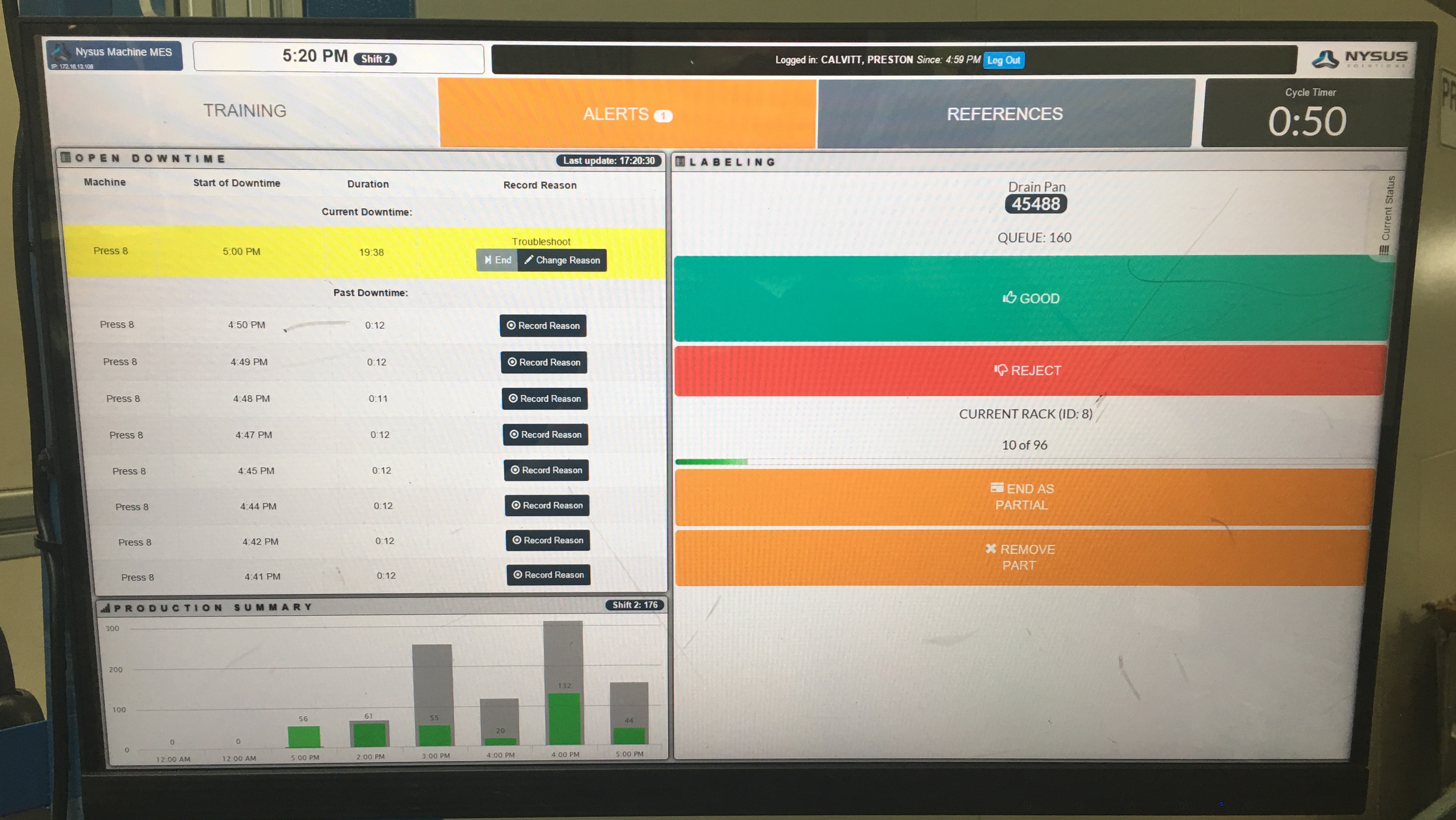

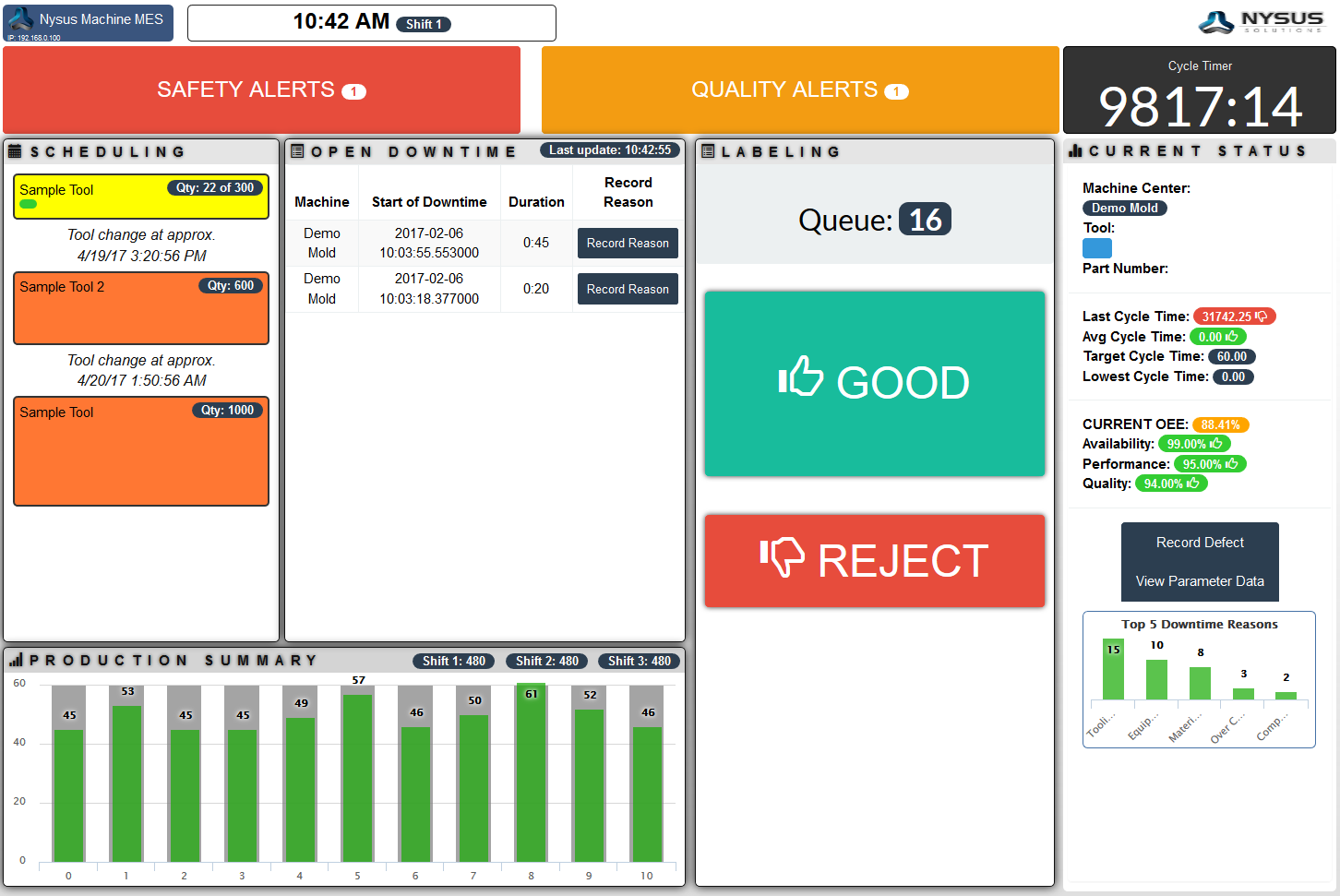

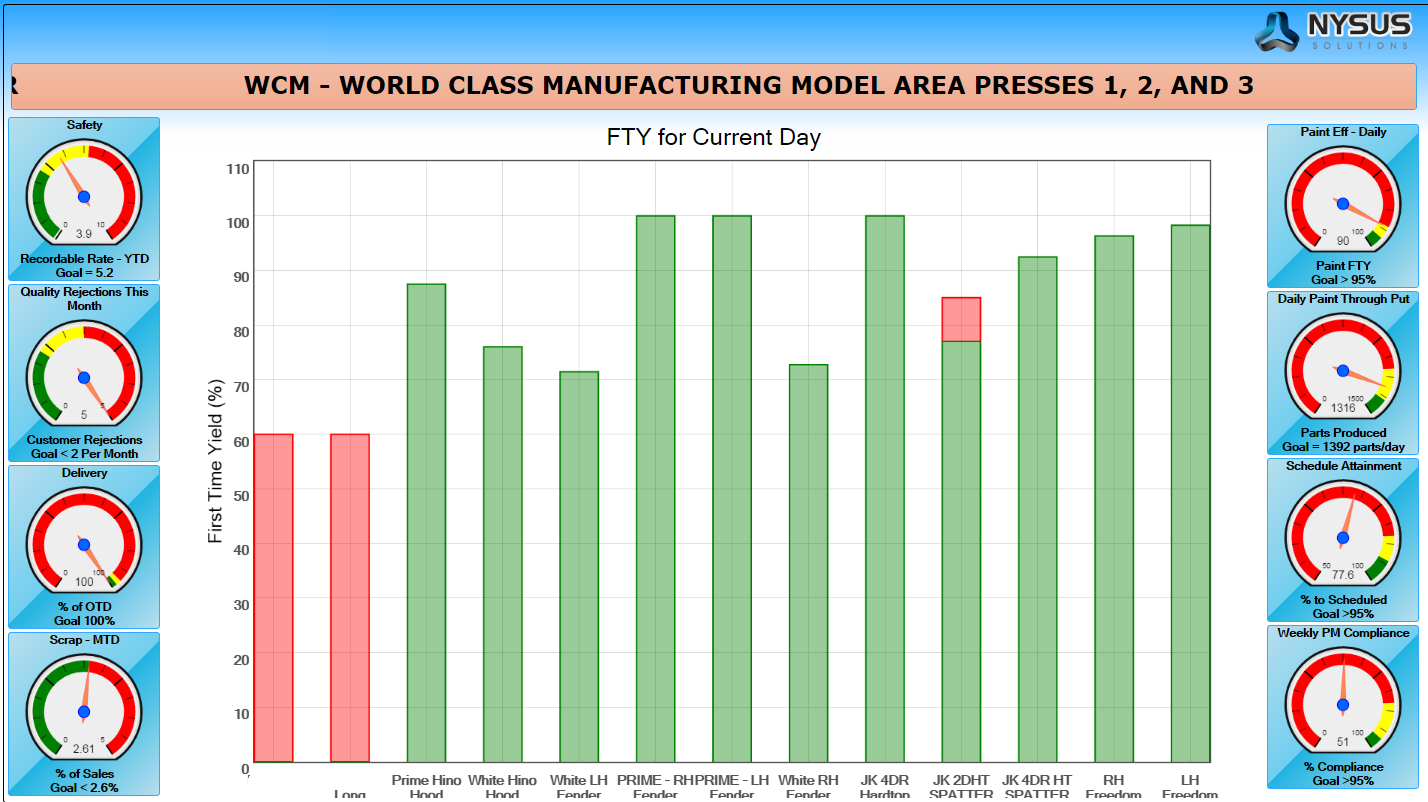

Machine MES

The Nysus Solutions Machine Manufacturing Execution System is designed to ensure the highest levels of efficiencies for capital equipment. Through direct machine integration, all critical parameters are collected and monitored including cycle times, defective material, downtime, OEE, and process specific parameters. Typical applications include injection molding, blow molding, stamping, extrusion, machining, grinding, polishing, and welding processes.

Integration Makes the Difference

There are many companies that “sell MES software”, but at Nysus Solutions, our dedication to a successful integration is what sets us apart. We have a highly qualified team of manufacturing professionals who will work with your team to ensure that your manufacturing execution system installation is a success. With the ability to easily customize the system to fit your exact requirements, you can be sure the Nysus Solutions Manufacturing Execution System will become an indispensable part of your manufacturing organization.

Manufacturing Execution Systems

Nysus Solutions MES provides a common user interface across all systems and can be customized to fit specific user requirements like text language and images.

Direct PLC Integration

The Nysus Solutions Manufacturing Execution Systems integrate directly to all makes and models of programmable logic controllers and do not require additional third party software.

Automated Work Instructions

Work instructions are easily maintained with options for images, text formatting and mass customization of products and processes.

Bar Code/RFID Tracking

Product traceability is a key component of the Nysus Solutions Manufacturing Execution Systems. Multiple tracking methods include traditional bar codes, 2D etched bar codes, and RFID tags. Create a complete product “birth certificate” to eliminate warranty issues and meet customer compliance requirements.