Quality Systems

- Home

- /

- Quality Systems

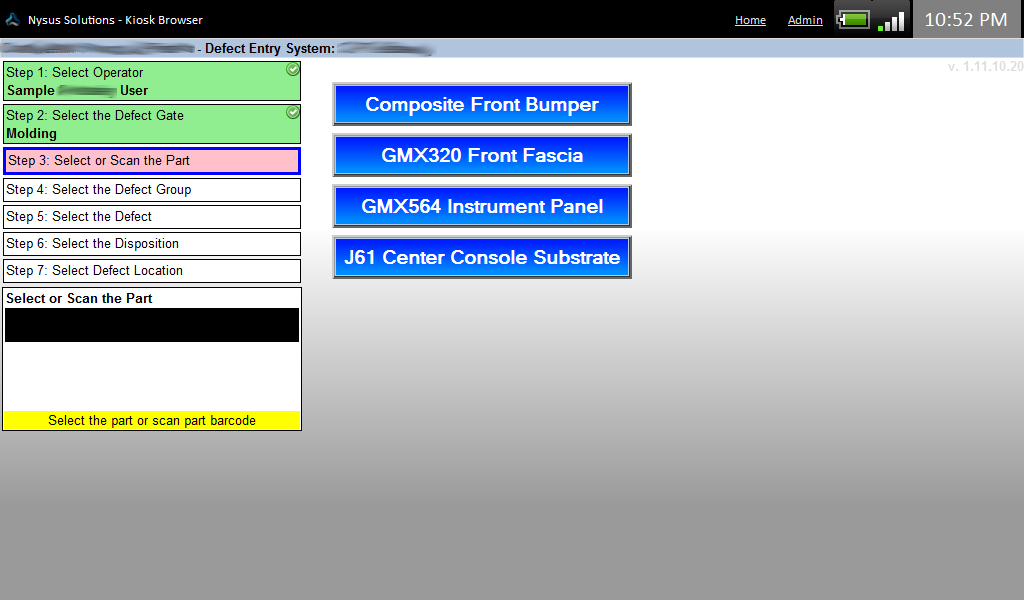

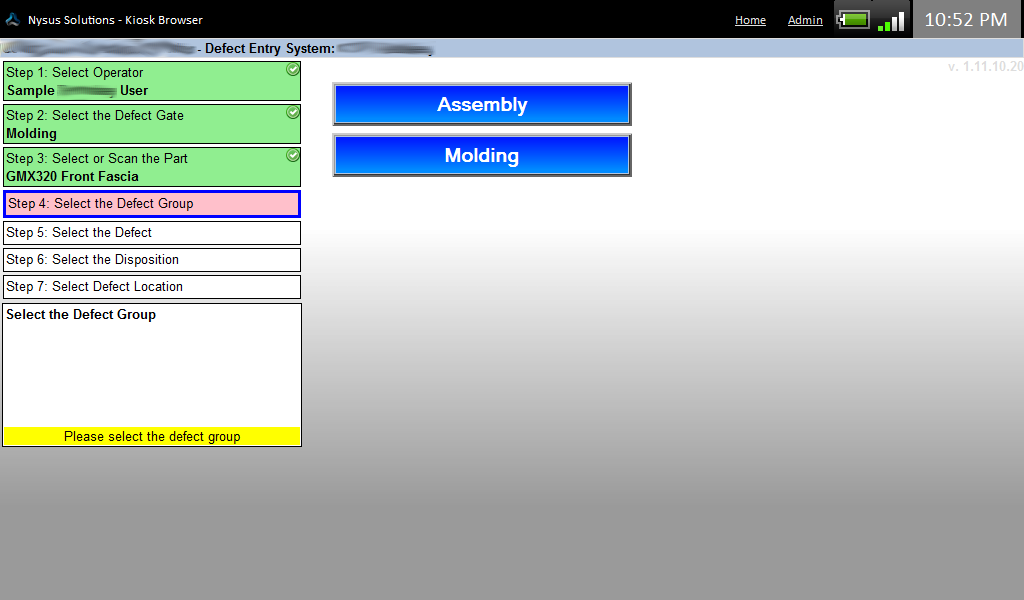

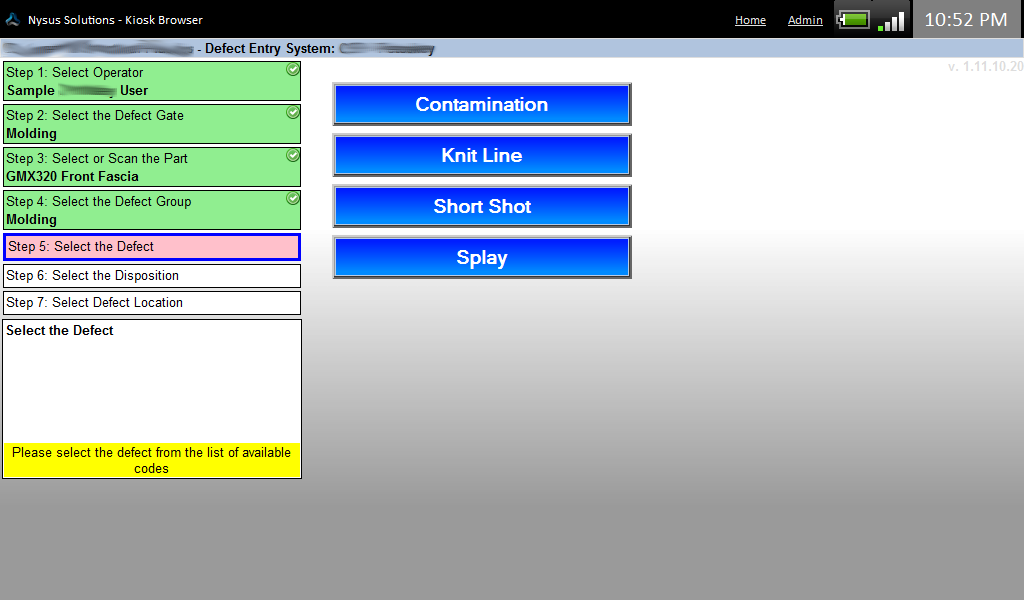

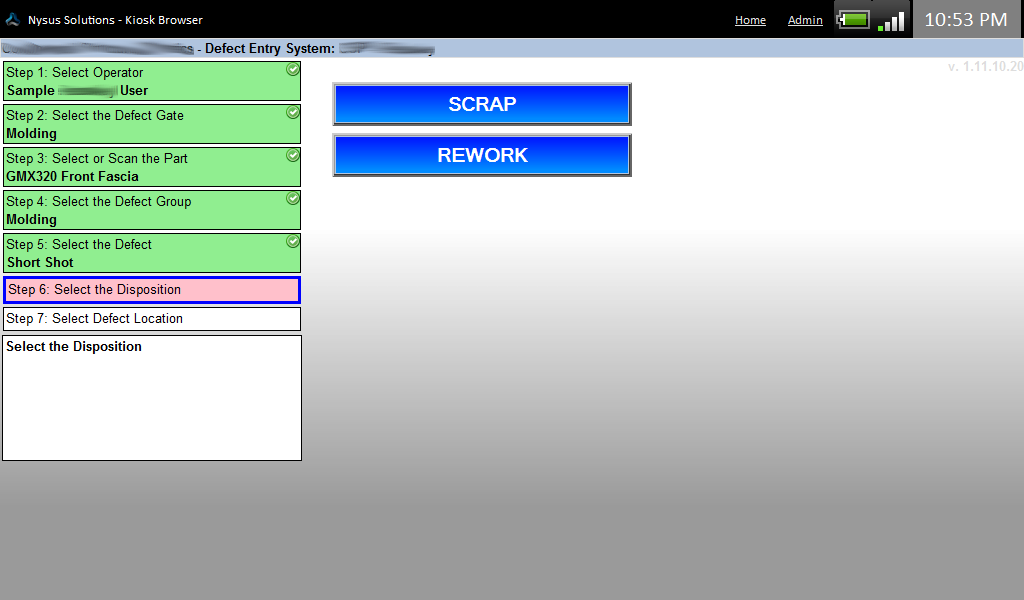

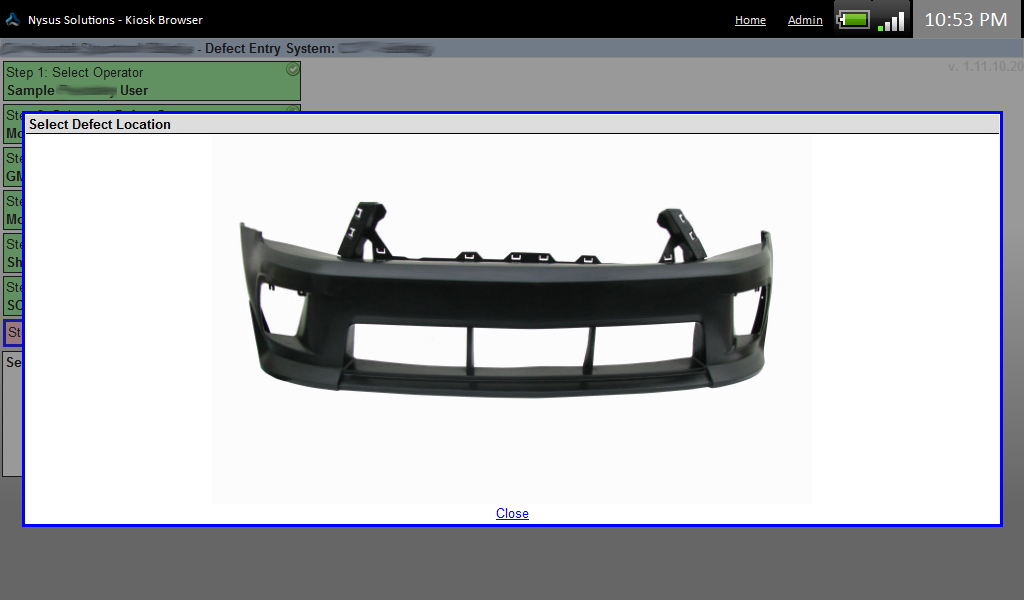

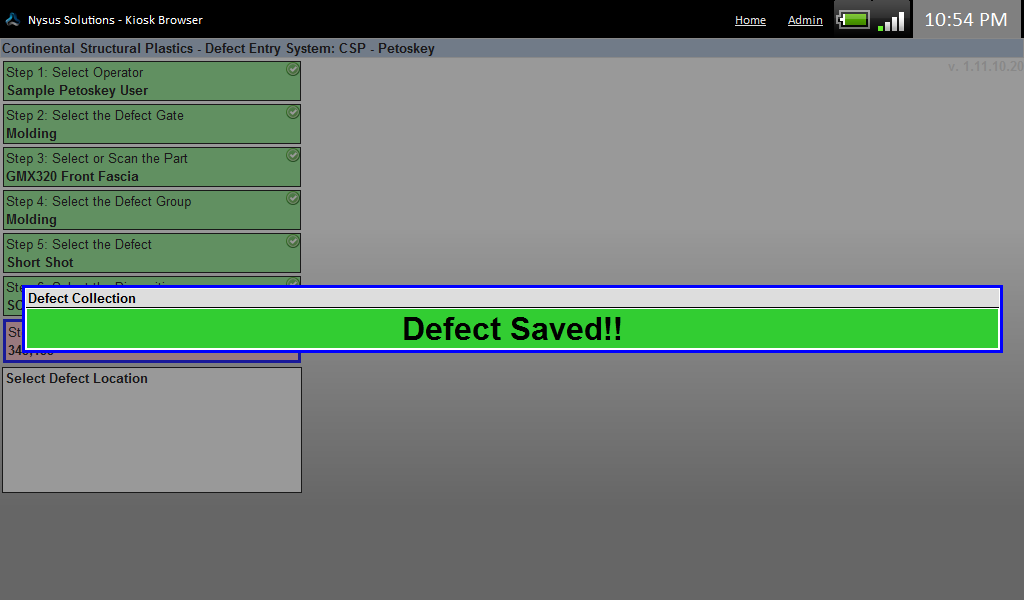

Defect Collection System

Quality System Overview

Find the Problem Sooner Solve the Problem Sooner

When a defect is created, it is critical to document the occurrence so true root cause analysis can be identified. The Nysus Solutions Defect Collection System can be a critical tool in determining where the issues originate and trends that could be affecting your manufacutring processes.

Features

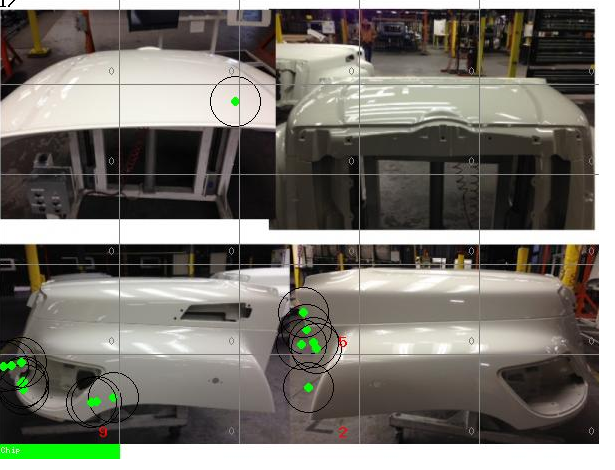

- Highlight defect patterns including location

- Provides time stamping of all defect occurrences

- Tracks defect by type or reason code

- Key tool in root cause analysis of defects

- Integrate to Nysus Solutions MES to allow for FTY reporting

- Integrate data with MRP system for scrap transactions via batch flat-file integration or XML web services

- Scatter plot of defect locations by type, part, defect group, defect etc.

- First Time (FTC) Yield Reports

- Defect occurrences by line, product type, defect group, defect type, associate or time.

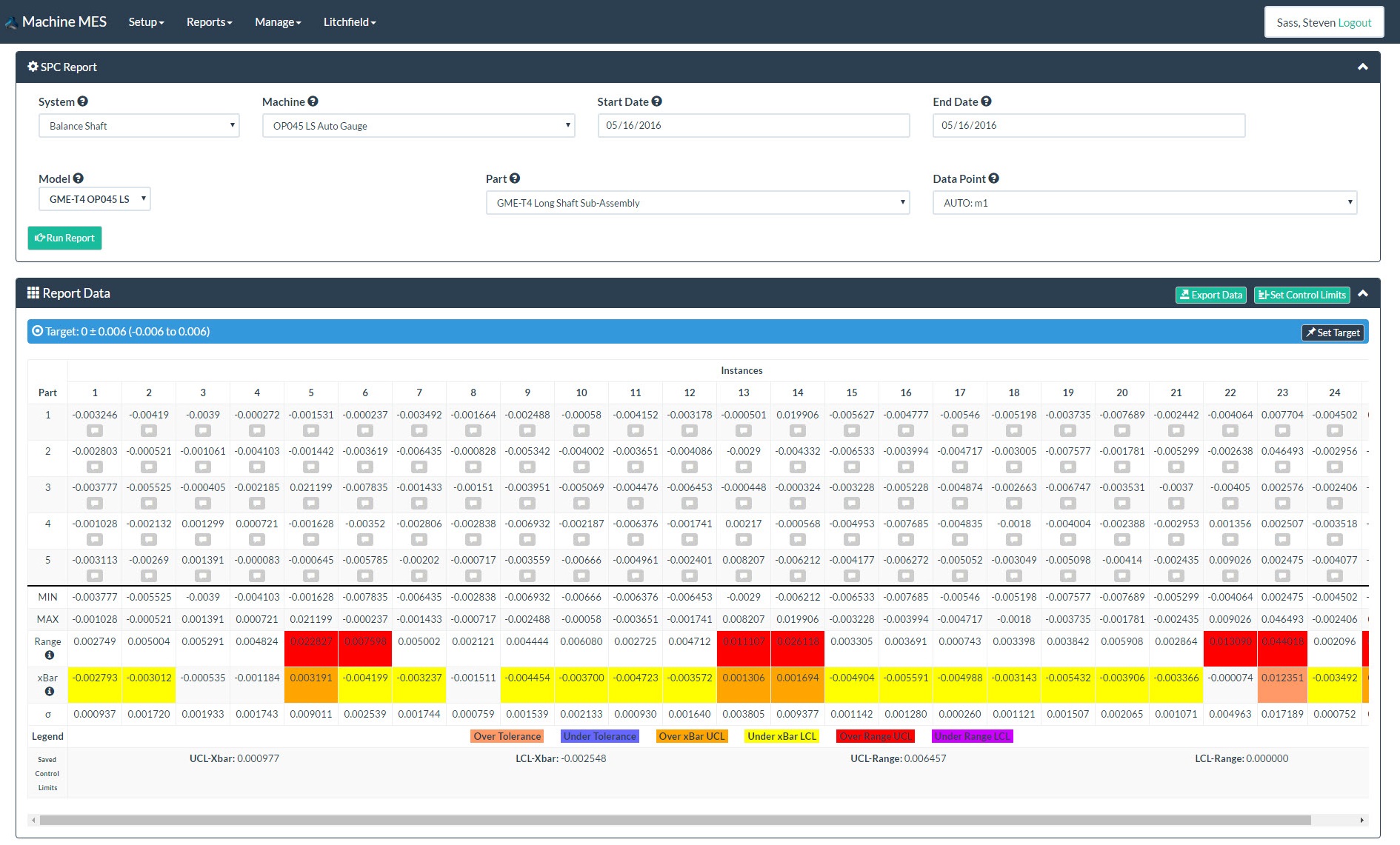

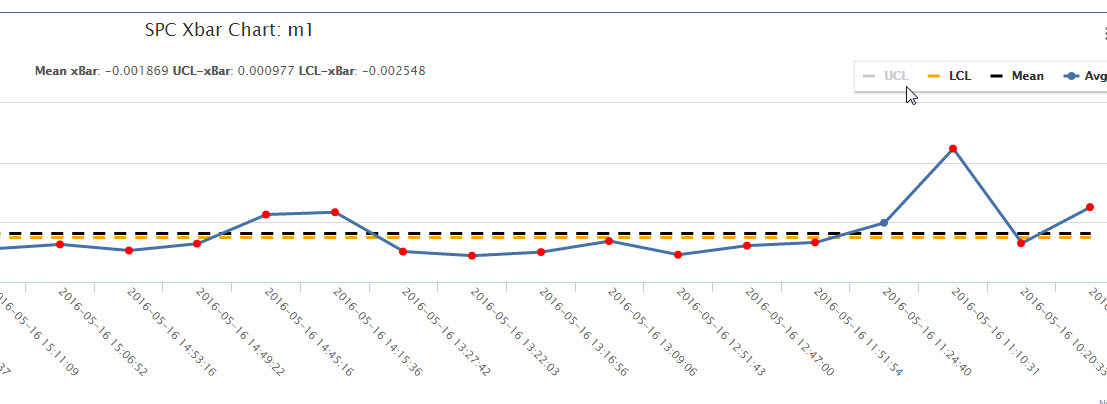

Statistical Process Control

Quality Assurance through the Web Automatic Problem Notification

The Statistical Process Control (SPC) System is a web application framed around tracking quality assurance data. Xbar and R charts are generated with automated emails sent when data is outside of the control limits.

Features

- Automated emails when data is outside of control limits

- Xbar and R charts are autogenerated as data is input

- Easy web access to Xbar and R charts

- Charts can be printed

- Image Upload available to ensure quality issues are tracked correctly

- Emails autogenerated when data is outside of control limits

- Data is filterable by date to check previous data